About

Masterpiece Technologies BV, a leading OEM in the RF, Microwave, and Antennas development sectors, proudly serves a diverse range of industries, including defence, military, and homeland security, among others.

In addition to our core offerings, Masterpiece Technologies is dedicated to advancing the field of RF, microwave components, and antennas solutions through continuous research and development, ensuring our technologies lead the market in innovation and efficiency.

Our expertise spans up to 40 GHz, enabling us to deliver cutting-edge solutions for high-frequency applications. We excel in both build-to-spec and build-to-print services, tailored to meet the unique requirements of these critical sectors. Our products are engineered to perform reliably in the most challenging environmental conditions.

Moreover, we specialize in addressing Electromagnetic Interference (EMI) and environmental concerns, ensuring our systems operate flawlessly in environments sensitive to electromagnetic disruptions and in extreme conditions. With our advanced simulation techniques, the Masterpiece Technologies engineering department consistently delivers innovative and dependable products that enhance communication, surveillance, and security infrastructures.

Our unwavering dedication to safety, security, and efficiency establishes us as a trusted partner in mission-critical operations globally. Our commitment to leading-edge technology and excellence ensures we stay at the forefront of our industry, meeting the stringent demands of our clients while overcoming challenges related to EMI and environmental factors.

We are committed to providing efficient, cost-effective solutions that not only meet but exceed our customers' requirements, ensuring timely delivery and utmost satisfaction. Our approach combines technical prowess with a deep understanding of the needs of the sectors we serve, making Masterpiece Technologies a key ally in achieving operational success.

Products

V/UHF RFDU

Why Choose Us?

Our Mission:

At Masterpiece Technologies BV, we are committed to delivering innovative, tailor-made RF and microwave communication and telemetry solutions designed for sea, ground, and air applications. Our focus is on developing cutting-edge technologies that meet a broad spectrum of electrical and environmental specifications, catering to the diverse needs of the defence, homeland security, and civil markets. Our goal is to exceed the expectations of our customers by providing high-performance solutions tailored to the unique challenges of each sector we serve.

Custom Solution Development:

We work closely with our customers to develop custom solutions that precisely meet their specifications. We have the ability to serve customers worldwide, and we have proven logistical capabilities that ensure smooth delivery and deployment of solutions across different regions.

Quality Assurance and Certifications:

We are proud to hold industry certifications such as AS9100D and ISO 9001 which testify to our rigorous quality standards and commitment to excellence.

Partnerships and Collaborations:

We believe in creating value through collaboration. Our partnerships with leading companies and (academic institutions-optional) drive innovation, keeping us at the forefront of technological advancements. We invite you to explore how our expertise can benefit your projects, ensuring success through unparalleled solutions and support.

Case Studies

Case Study: Masterpiece Technologies together with Elipse Engineering Ltd ~ RFDU Unit Revolution

Introduction

The Masterpiece RF team together with Elipse Engineering, both leaders in radio frequency technology, faced the challenge of manufacturing a Radio Frequency Distribution Unit (RFDU) that was initially specified to be 5-6U in size with connectorized components. Both RF teams, committed to exceeding expectations, proposed an innovative solution that not only fulfilled the customer's requirements but also set a new standard for the production process.

Challenge

The task was to design an RFDU that met strict size specifications while maintaining cost-effectiveness, reliability, and efficient heat management.

Solution

The RF teams of Masterpiece Tech and Elipse Engineering developed together an innovative approach by recommending the adoption of Surface Mount Technology (SMT) components. This pivotal choice resulted in the development of a sleek 1U drawer, effectively halving the unit's size and substantially lowering production expenses. Furthermore, the engineers crafted a tailored Printed Circuit Board (PCB) circuit to enhance the new design further.

Implementation

-

SMT Integration:

The use of SMT components facilitated a significant decrease in unit size while also enhancing performance, reducing costs, and optimizing heat dispersion. -

Custom PCB Circuit: Both RF teams meticulously crafted a specialized PCB circuit tailored to the unique requirements of the RFDU unit. This bespoke design played a crucial role in optimizing electrical performance and overall functionality.

-

Cost-Efficiency: The innovative use of SMT components, coupled with the streamlined design, resulted in a 50% reduction in production costs, exceeding initial expectations.

-

Enhanced Reliability: The new design not only met the specified electrical requirements but also enhanced Mean Time Between Failures (MTBF) due to improved heat distribution and component efficiency.

Results

-

Size Revolution: Masterpiece Tech together with Elipse Engineering successfully transformed the RFDU unit from a 5-6U configuration to an ultra-compact 1U drawer, meeting both space constraints and industry standards.

-

Cost Savings: The implementation of SMT components and the redesigned unit led to a substantial 50% reduction in production costs, offering significant financial advantages.

-

Reliability Boost: The optimized design and efficient heat distribution resulted in a notable improvement in the unit's reliability, ensuring consistent performance under diverse conditions.

Conclusion

Masterpiece Tech and Elipse Engineering's RF teams visionary approach not only met the client's initial requirements but set a new standard for RFDU unit manufacturing.

By embracing SMT components and redefining the design, Masterpiece Tech and Elipse Engineering showcased its commitment to innovation, cost-effectiveness, and reliability.

This case study exemplifies our ability to deliver groundbreaking solutions that transcend conventional expectations and position’s us as an industry leader in RF technology.

Support

Support: Our dedicated team at Masterpiece Tech is committed to your success, providing

comprehensive support and expertise at every stage of your project. We are here to assist you every

step of the way, ensuring a seamless and successful project outcome.

Our Team

At Masterpiece Technologies, our team boasts a wealth of expertise in RF and microwave technologies, specializing in the design and development of both passive microwave modules and active digital and analog modules.

Comprising highly skilled and experienced professionals, our team includes electrical and mechanical engineers, RF technicians, antenna specialists, and experts in both digital and analog RF technologies.

Additionally, our talented developers and integrators play a crucial role in delivering comprehensive

solutions.

Together, we are dedicated to pushing the boundaries of innovation and delivering

exceptional results for our clients.

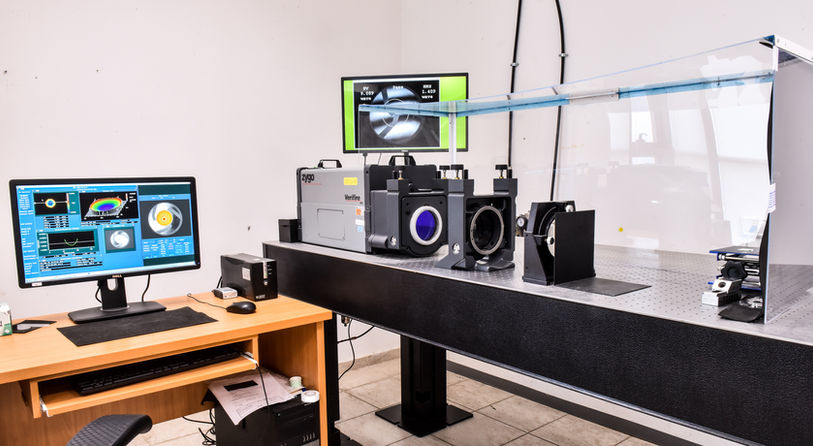

QA and Metrology

With sapphire being a high-performance product that is highly engineered with unique requirements, Masterpiece Technologies strongly believes that one cannot sell high-performing materials if one cannot measure them!

In support of this philosophy, we have invested in metrology tools, equipment, and facilities to achieve our goals.

Specific capabilities:

Varian Cary 50 spectrometer for measuring sapphire transmission and absorption from 190 to 1100 nm.

Zygo New View: This is an interferometric, non-contact surface measurement system that can measure sapphire surface finish and roughness to the angstrom level.

The Zygo Verifire is a non-contact optical interfometer that measures sapphire optical flatness, transmitted wavefront error (TWE), power, and irregularity at the fractional wave level.

Rigaku X-ray for sapphire crystal orientation measurements.

Numerous optical comparators, high-power imaging, and microscope systems are available for physical measurement and inspection. Laser marking capability for part numbering and serialization to aid in compliance with traceability and tracking.

We run rigorous controls to meet all customer inspection, certification, CofC, and other requirements.

Masterpiece Technologies does not only fully control the process from raw material through to final delivery, but we also fully support all deliveries with inspection and certification for full compliance.