Sapphire Products

About

Masterpiece Technologies is a manufacturer of sapphire products. We are ISO 9001 certified.

Masterpiece Technologies B.V. is a world leader as a sapphire manufacturer, providing quality sapphire components. We, at Masterpiece Technologies, have expertise in shaping, drilling, and polishing sapphires with very high precision. And we grow our own sapphire!

Our sapphire experience ranges from semiconductors to medical, optical, and R&D applications. Masterpiece Technologies has been "hands-on" with many of the current sapphire applications worldwide. We partner with our customers to develop and support the best solutions possible for their application challenges.

Examples of Unique Sapphire Components and Custom-Fabricated Sapphire:

-

Threaded sapphire components: for lift pins and other applications.

-

Complex geometries: unique complex shapes with precision holes and features.

-

Complex geometries: thin-walled showerheads including 151 holes sized and positioned to create uniform plasma flow over a wafer surface.

-

Complex geometries: delicate shapes for plasma components.

-

Integrated flanges on sapphire tubes for high vacuum applications.

Our sapphire products include:

-

Sapphire windows ranging in size from 10 mm to 350 mm (13.5") with optical flatness in the fractional wave range as needed.

-

Precision sapphire optics for medical laser applications, imaging, and SWIR camera applications.

-

Sapphire lift pins with varying lengths and simple or radiused end finish, complex shaped ends for flush mounting in wafer chucks, and threaded, and shaped versions.

-

Optical light guides with polished diameters and ends for sensors and light transmission applications in high temperatures and hostile environments.

-

Sapphire tubes for plasma generation in semiconductor process equipment, thermocouple protection tubes, hostile environment applications, and UV applications for sterilization and water purification.

-

Sapphire injectors are sapphire tubes with closed or precision drilled ends that are used to dose reactants at high temperatures or in hostile environments.

-

Complex sapphire shapes for focus rings, and sapphire plasma showerheads for plasma distribution.

Semiconductors

Sapphire offers the highest strength, purity, and durability in aggressive processing environments using NF3 and CF4. Sapphire components provide long lifetimes, reduced particulation, and increased uptime.

Sapphire components are used in a range of semiconductor equipment applications, including:

-

Sapphire tubes: replacing quartz, sapphire plasma tubes have been proven to be an enabling technology.

-

Plasma injector nozzles: replacing ceramic and quartz, sapphire injectors reduce particulation, increase the time between PM’s, increase uptime, and reduce COO.

-

Sapphire chamber windows and viewports: these offer very long life and consistent transmission.

-

Heater and microwave windows: these provide high transmission and long life.

-

Sapphire lift pins and guide/alignment pins dramatically improve strength over quartz versions, with no erosion over time. They offer dramatic improvements in particle performance over ceramic versions.

-

Optical light guides and sensor probes can be used in temperatures above the quartz devitrification limit and in hostile chemical environments.

-

Thermocouple protection sheaths: replacing quartz and silicon carbide (SiC) for multipoint thermocouples, they can be used both in horizontal and vertical furnaces.

-

Gas delivery and showerhead components: long life in aggressive plasma

-

Sapphire dummy wafers.

Sapphire Medical Optics & Laser Optics

Sapphire is used in a range of medical and other applications. The key reasons for that are its unique qualities.

Sapphire has high strength and durability, biocompatibility, spectral transmission from 200 to 3500 nm, and a thermal conductivity twenty-eight times higher than quartz or glass optics. All these properties are combined to optimize system performance.

-

Sapphire windows for intense pulsed light and cosmetic laser surgical devices

-

Sapphire filters and mirrors.

-

Prisms fabricated to customer specifications, including plano/plano, plano/convex or concave, concave/convex, rod lenses, and prisms.

-

Sapphire lenses for sapphire medical optics, sapphire laser optics, and imaging application

Sizes range from less than 3 mm to over 370 mm in diameter, and thicknesses vary from 0.1 mm to over 60 mm and above. We can achieve a flatness of less than Lambda/10. Surface Finish Ra greater than 0.5nm and parallelism up to 2 arc sec

Technical Information

Synthetic sapphire is a transparent single crystal of 99.99% pure Al2O3 that offers broad spectral transmission combined with high thermal conductivity, high strength, and high temperature capability. It is one of the most chemically durable materials known.

Chemical resistance: sapphire is highly inert and resistant to attack in most process environments, including hydrofluoric acid and fluorine plasma (NF3, CF4).

Sapphire applications are found in semiconductors and other process environments.

Mechanical properties: high strength. With strength and stiffness six times higher than quartz, combined with excellent wear and scratch resistance, sapphire becomes the high-performance choice.

Thermal properties: sapphire is usable at temperatures near 2000 °C and has a thermal conductivity of 28 X for quartz, making it useful in a variety of specialty applications. Sapphire provides a high, stable dielectric constant with the electrical insulation required for electronic substrates, RF, microwave transmitting windows, and tubes.

Electrical properties: sapphire provides a high, stable dielectric constant with the electrical insulation required for electronic substrates, RF and microwave transmitting windows, and tubes.

Surface properties: with high hardness and uniformity, sapphire can be polished to very tight flatness levels. 1/10th and even 1/20th wave flatness and Angstrom level surface finishes.

Wear properties: high strength and chemical durability combine to enable the production of dimensionally and optically stable components for long life use.

Capabilities

Sapphire is one of the hardest, strongest, and most chemically and mechanically durable materials.

With vertical integration and complete fabrication, including shaping, grinding, drilling, and polishing, Masterpiece Technologies can offer complete customer solutions. Our manufacturing is completely custom-tailored to handle the challenges involved in processing sapphire.

Differentiating Masterpiece Technologies from many producers using a single production method, we grow our own sapphire using two methods: EFG/Stephanove and Kyropolus. This gives us a broader range of material quality and form factor choices to provide a solution best matched to the customer's requirements in terms of size, shape, quality, and cost.

We are able to support a very broad range of applications, from small windows to complex 3D shapes with holes, passageways, and threaded features.

Sapphire Laser marking, Cleaning, and Packaging

Masterpiece Technologies meets OEM and industry standards for our range of customers by offering services that include laser marking, cleanroom cleaning, and packaging per semiconductor OEM specifications.

Masterpiece Technologies' systems are in place to support our sapphire customers in the semiconductor industry with full CE (Copy Exact) compliance. Our systems include cleaning, labeling, and packaging to meet industry Class 1000 and better requirements.

Masterpiece Technologies supports customer reviews and audits as required. Services subcontracted to approved OEM cleaning and packaging suppliers are also routinely audited for full compliance.

With over 15 years of supporting the semiconductor industry with a range of sapphire products, our systems evolve consistently to meet the ever-changing requirements for cleaning and packaging.

Sapphire Coating and Metallization

UV filters and UV blockers: often used for "eye-safe" protection on sapphire windows, they block excess UV from being emitted from a process chamber or sensor viewport.

QA and Metrology

With sapphire being a high-performance product that is highly engineered with unique requirements, Masterpiece Technologies strongly believes that one cannot sell high-performing materials if one cannot measure them!

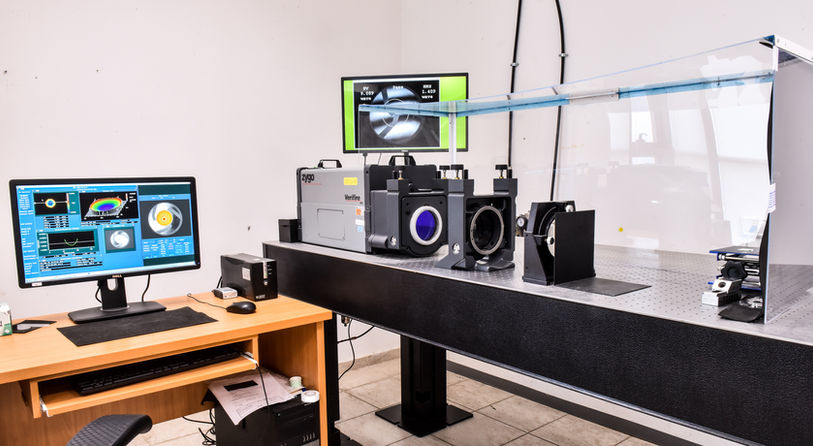

In support of this philosophy, we have invested in metrology tools, equipment, and facilities to achieve our goals.

Specific capabilities:

Varian Cary 50 spectrometer for measuring sapphire transmission and absorption from 190 to 1100 nm.

Zygo New View: This is an interferometric, non-contact surface measurement system that can measure sapphire surface finish and roughness to the angstrom level.

The Zygo Verifire is a non-contact optical interfometer that measures sapphire optical flatness, transmitted wavefront error (TWE), power, and irregularity at the fractional wave level.

Rigaku X-ray for sapphire crystal orientation measurements.

Numerous optical comparators, high-power imaging, and microscope systems are available for physical measurement and inspection. Laser marking capability for part numbering and serialization to aid in compliance with traceability and tracking.

We run rigorous controls to meet all customer inspection, certification, CofC, and other requirements.

Masterpiece Technologies does not only fully control the process from raw material through to final delivery, but we also fully support all deliveries with inspection and certification for full compliance.